Mukayamba pulojekiti yosangalatsa - kaya ikumanga makina olondola komanso olakwika a CNC apakompyuta kapena mkono woyenda bwino wa robotic - kusankha zida zamphamvu zoyenera nthawi zambiri ndiye chinsinsi chakuchita bwino. Pakati pazigawo zambiri zopha, ma micro stepper motors akhala chisankho chokondedwa kwa opanga, mainjiniya, ndi opanga chifukwa chakuwongolera kwawo kotseguka, kusungirako bwino kwa torque, komanso kutsika mtengo.

Komabe, poyang'anizana ndi mitundu ingapo yamitundu ndi magawo ovuta, mungasankhire bwanji injini yaying'ono yabwino kwambiri ya loboti yanu kapena makina a CNC? Kusankha njira yolakwika kungayambitse kulondola kwapang'onopang'ono, mphamvu zosakwanira, kapena kulephera kwa polojekiti. Bukhuli likhala ngati buku lanu lomaliza losankhira, ndikukutengerani pang'onopang'ono kuti mufotokozere zonse zofunika ndikupanga zisankho zanzeru.

Khwerero 1: Kumvetsetsa zofunika kwambiri - kusiyana kwakukulu pakati pa maloboti ndi CNC

Musanayang'ane magawo aliwonse, muyenera kufotokozera zofunikira pakugwiritsa ntchito galimoto yanu.

Mapulojekiti a maloboti (monga mikono yamaloboti, maloboti am'manja):

Zofunikira zazikulu: kuyankha mwamphamvu, kulemera, kukula, ndi magwiridwe antchito. Malumikizidwe a maloboti amafunikira kuyimitsidwa pafupipafupi, kuthamanga kosinthika, ndi kusintha komwe kumayendera, ndipo kulemera kwagalimoto kumakhudza mwachindunji kuchuluka kwamafuta onse ndikugwiritsa ntchito mphamvu.

Zizindikiro zazikulu: Samalirani kwambiri ma curve a torque (makamaka apakati mpaka ma torque othamanga kwambiri) komanso kuchuluka kwa kulemera kwake.

CNC makina zida (monga 3-olamulira chosema makina, laser kudula makina):

Zofunikira zazikulu: kukankhira, kusalala, kusunga torque, komanso kulondola. Zida zamakina a CNC ziyenera kuthana ndi kukana kwakukulu panthawi yodula kapena kuzokota, kukhalabe ndikuyenda bwino kuti mupewe kugwedezeka, ndikuyika bwino.

Zizindikiro zazikulu: Samalirani kwambiri kusunga torque pa liwiro lotsika, kusintha masitepe ang'onoang'ono kuti muchepetse kugwedezeka, komanso kulimba kwagalimoto.

Kumvetsetsa kusiyana kwakukulu kumeneku ndiko maziko a zosankha zonse zotsatila.

Khwerero 2: Kutanthauzira kwa Magawo Asanu Ofunikira a Micro stepper Motors

Nawa magawo asanu ofunikira omwe muyenera kulabadira mu bukhu la data.

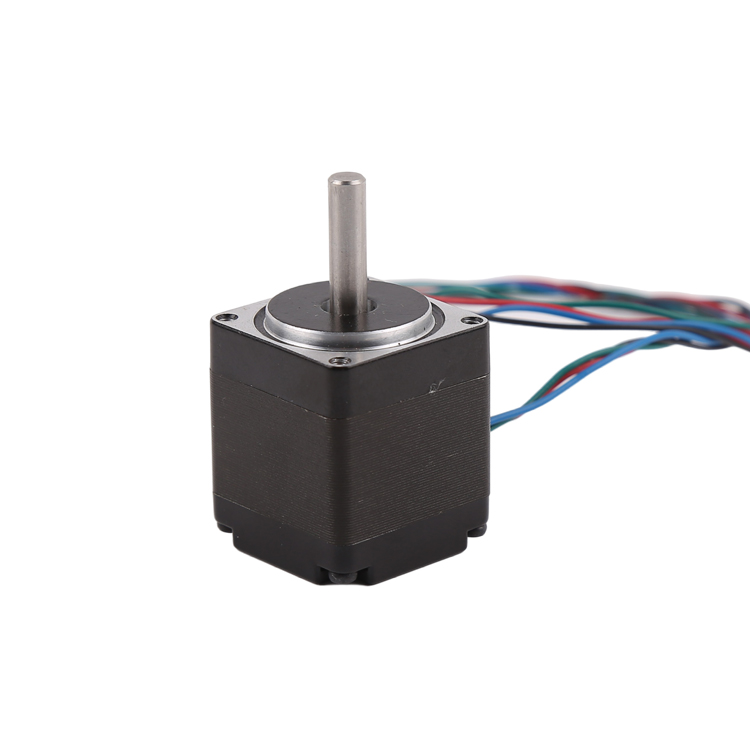

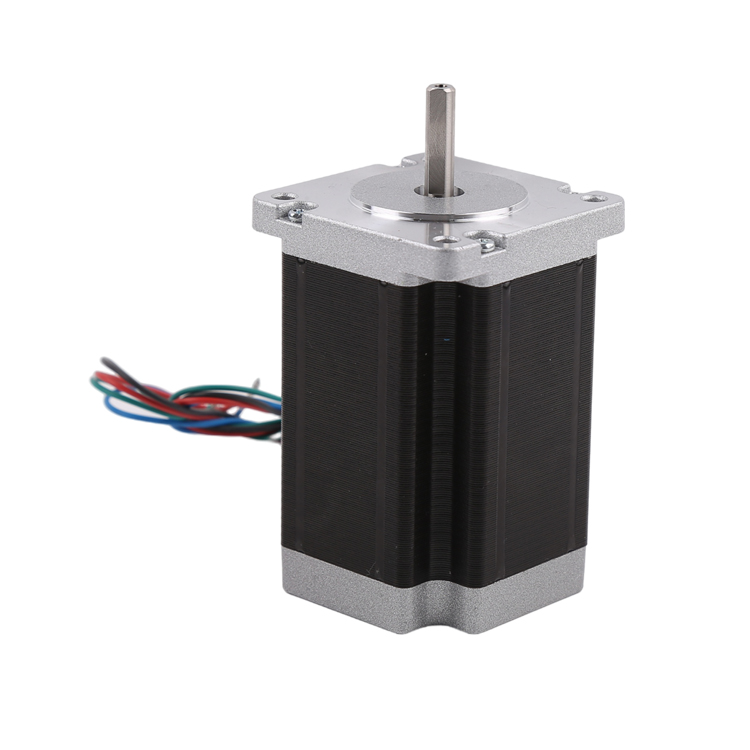

1. Kukula ndi torque - mwala wapangodya wa mphamvu

Kukula (nambala yoyambira pamakina): nthawi zambiri amawonetsedwa mu millimeters (monga NEMA 11, 17, 23). Muyezo wa NEMA umatanthauzira kukula kwa ma mota, osati momwe amagwirira ntchito. NEMA 17 ndiye kukula kodziwika bwino kwa maloboti apakompyuta ndi CNC, kupeza bwino pakati pa kukula ndi torque. NEMA 11/14 yaying'ono ndiyoyenera kulumikizana ndi maloboti opepuka; NEMA 23 yayikulu ndi yoyenera zida zazikulu zamakina a CNC.

Sungani torque: Unit ndi N · cm kapena Oz · in. Iyi ndiye torque yayikulu yomwe injini imatha kupanga ikayendetsedwa koma osazungulira. Ichi ndiye chizindikiro chofunikira kwambiri poyezera mphamvu yagalimoto. Pazida zamakina a CNC, mufunika torque yokwanira kuti mupewe mphamvu zodulira; Kwa ma robot, ndikofunikira kuwerengera torque yayikulu yofunikira pamalumikizidwe.

Kodi mungayerekeze torque yofunika bwanji?

Pazida zamakina a CNC, lamulo loyipa la chala chachikulu ndikuti torque yomwe imatha kupereka osachepera 20-30N (pafupifupi 2-3 kilogalamu) axial thrust ikufunika. Izi zimafunika kusinthidwa kudzera mu kutsogolera ndi mphamvu ya screw. Kwa maloboti, mawerengedwe ovuta amafunikira kutengera kutalika kwa mkono, kulemera kwake, komanso kuthamanga. Onetsetsani kuti mwasiya malire a 30% -50% kuti mupirire zinthu zosatsimikizika monga mikangano ndi inertia.

2.Masitepe angle ndi kulondola - moyo wa sitepe

Khwerero ngodya: monga 1.8 ° kapena 0,9 °. Galimoto ya 1.8 ° imazungulira kamodzi pa masitepe 200, pamene injini ya 0,9 ° imafuna masitepe 400. Kuchepa kwa ngodya ya masitepe, kumapangitsa kuti injiniyo ikhale yolondola kwambiri. Motor ya 0.9 ° nthawi zambiri imakhala yosalala ikamayenda pa liwiro lotsika.

3. Panopa ndi Voltage - Kufananiza kwa Madalaivala

Gawo lapano: Unit ndi Ampere (A). Uwu ndiye mphamvu yayikulu kwambiri yomwe gawo lililonse lamagetsi limatha kupirira. Parameter iyi imasankha mwachindunji galimoto yomwe muyenera kusankha. Kuthekera kwaposachedwa kwa dalaivala kuyenera kufananizidwa ndi mota.

Mphamvu yamagetsi: Ma motors nthawi zambiri amavotera ma voliyumu awo, koma magetsi enieni amatha kukhala okwera kwambiri kuposa awa (amatsimikiziridwa ndi dalaivala). Magetsi okwera kwambiri amathandizira kupititsa patsogolo kuthamanga kwa injini.

4. Inductance ndi ntchito yothamanga kwambiri - zinthu zazikulu zomwe zimanyalanyazidwa mosavuta

Inductance ndiye chinthu chofunikira kwambiri chomwe chimakhudza ma torque othamanga kwambiri agalimoto. Ma motors otsika kwambiri amatha kukhazikitsa pano mwachangu, zomwe zimapangitsa kuti azigwira bwino ntchito pa liwiro lalikulu. Ngati mfundo za loboti yanu ziyenera kusinthasintha mwachangu, kapena ngati makina anu a CNC akufuna kuwonjezera kuchuluka kwa chakudya, muyenera kuyika patsogolo kusankha mitundu yokhala ndi inductance yochepa.

5. Mtundu wa shaft ndi njira yotuluka - tsatanetsatane wa kulumikizana kwamakina

Mitundu ya shaft: optical axis, single flat shaft, double shaft shaft, gear shaft. Kucheka kwamtundu wa D (shaft single flat shaft) ndikofala kwambiri ndipo kumatha kuletsa kulumikizanako kuti zisaterereka.

Njira yotuluka: otuluka mwachindunji kapena pulagi-in. Njira ya pulagi (monga 4-pin kapena 6-pini ndege ya ndege) ndiyosavuta kukhazikitsa ndi kukonza, ndipo ndi chisankho chaukadaulo.

Khwerero 3: Wokondedwa wofunikira - momwe mungasankhire woyendetsa galimoto

Injiniyo siyingagwire ntchito ndipo iyenera kuphatikizidwa ndi woyendetsa galimoto. Ubwino wa dalaivala umatsimikizira mwachindunji ntchito yomaliza ya dongosolo.

Microstep: Gawani gawo lonse kukhala ma microsteps angapo (monga 16, 32, 256 microsteps). Ntchito yayikulu yakupondaponda kwapang'onopang'ono ndikupangitsa kuyenda kwagalimoto kukhala kosalala kwambiri, kuchepetsa kwambiri kugwedezeka ndi phokoso, komwe kuli kofunikira pamtundu wa zida zamakina a CNC.

Ulamuliro wapano: Madalaivala abwino kwambiri amakhala ndi theka la ntchito yapano. Dzichepetseni nokha injini ikamayima, kuchepetsa kutentha komanso kugwiritsa ntchito mphamvu.

tchipisi/module zoyendetsa wamba:

Mulingo wolowera: A4988- Mtengo wotsika, woyenera ntchito zosavuta za loboti.

Kusankha Kwakukulu: TMC2208/TMC2209- Imathandizira kuyendetsa mwakachetechete (StealthShop mode), imayenda mwakachetechete kwambiri, ndi chisankho chabwino kwambiri pazida zamakina a CNC, ndipo imapereka magwiridwe antchito apamwamba kwambiri.

Kuchita kwakukulu: DRV8825/TB6600- imapereka chithandizo chapamwamba chamakono ndi magetsi, oyenera ntchito zomwe zimafuna torque yayikulu.

Kumbukirani: woyendetsa bwino amatha kukulitsa kuthekera kwa injini.

Khwerero 4: Njira Yosankhira Bwino ndi Zolakwika Zodziwika

Njira inayi yosankha:

Tanthauzani katundu: Fotokozani momveka bwino kulemera kwakukulu, kuthamanga kofunikira, ndi liwiro lomwe makina anu akuyenera kusuntha.

Werengerani torque: Gwiritsani ntchito chowerengera chapaintaneti kapena makina opangira makina kuti muyerekeze torque yofunikira.

Kusankhidwa koyambirira kwa injini: Sankhani mitundu 2-3 yotengera ma torque ndi kukula kwake, ndikufananiza ma curve awo amphamvu.

Match driver: Sankhani gawo loyendetsa loyenera komanso magetsi potengera momwe galimotoyo ilili komanso ntchito zofunika (monga osalankhula, kugawanika kwakukulu).

Zolakwika Zodziwika (Kupewa Maenje):

Malingaliro olakwika 1: Kukula kwa torque, kumakhala bwinoko. Kuchulukirachulukira kumatanthawuza ma motors akuluakulu, kulemera kwambiri, komanso kugwiritsa ntchito mphamvu zambiri, zomwe zimawononga kwambiri ma loboti.

Maganizo Olakwika 2:Ingoyang'anani pakusamalira torque ndikunyalanyaza torque yothamanga kwambiri. Injiniyo imakhala ndi torque yayikulu pama liwiro otsika, koma liwiro likamakula, torque imachepa. Onetsetsani kuti mwayang'ana tchati cha liwiro la torque.

Maganizo Olakwika 3: Mphamvu zosakwanira. Mphamvu yamagetsi ndiyo gwero lamphamvu la dongosolo. Mphamvu zopanda mphamvu sizingayendetse injiniyo kuti igwire ntchito yake yonse. Mphamvu yamagetsi iyenera kukhala pakati pa voteji ya dalaivala, ndipo mphamvu yomwe ilipo ikuyenera kukhala yoposa 60% ya kuchuluka kwa mafunde onse amagetsi.

Khwerero 5: Mfundo Zapamwamba - Kodi Tiyenera Kuganizira Liti Loop Systems Yotsekedwa?

Traditional stepper motors ndi lotseguka kuzungulira, ndipo ngati katundu ndi waukulu kwambiri ndi kuchititsa galimoto "kutaya sitepe", wolamulira sangathe kudziwa. Ichi ndi cholakwika chakupha pamapulogalamu omwe amafunikira kudalirika kwa 100%, monga makina a CNC amalonda.

The chotsekeka-loop stepper motor imaphatikiza encoder kumapeto kwa galimotoyo, yomwe imatha kuyang'anira malo munthawi yeniyeni ndikuwongolera zolakwika. Imaphatikiza zabwino zamakokedwe apamwamba kwa ma stepper motors ndi kudalirika kwa ma servo motors. Ngati polojekiti yanu:

Palibe chiopsezo chopatuka chomwe chimaloledwa.

Ndikofunikira kugwiritsa ntchito mokwanira magwiridwe antchito agalimoto (zotsekeka-zotsekeka zimatha kupereka kuthamanga kwambiri).

Amagwiritsidwa ntchito pazinthu zamalonda.

Chifukwa chake, kuyika ndalama mumayendedwe otsekeka otsika ndikofunikira.

Mapeto

Kusankha micro stepper motor yoyenera pa loboti yanu kapena makina a CNC ndiukadaulo wamakina womwe umafunika kuganiziridwa mozama zamakina, zamagetsi, ndi zowongolera. Palibe injini 'yabwino', koma injini 'yoyenera kwambiri' yokha.

Kuti mufotokoze mwachidule mfundo zazikuluzikulu, kuyambira pazomwe zimapangidwira, maloboti amaika patsogolo magwiridwe antchito ndi kulemera kwake, pomwe zida zamakina a CNC zimayika patsogolo ma torque ndi kukhazikika. Gwirani mwamphamvu pazigawo zazikulu za torque, zamakono, ndi inductance, ndikuzikonzekeretsa ndi dalaivala wabwino kwambiri komanso magetsi okwanira. Kupyolera mu chitsogozo cha nkhaniyi, ndikuyembekeza kuti mutha kupanga chisankho chabwino kwambiri cha polojekiti yanu yotsatira, kuonetsetsa kuti zomwe mwapanga zikuyenda molondola, mwamphamvu, komanso modalirika.

Nthawi yotumiza: Sep-25-2025