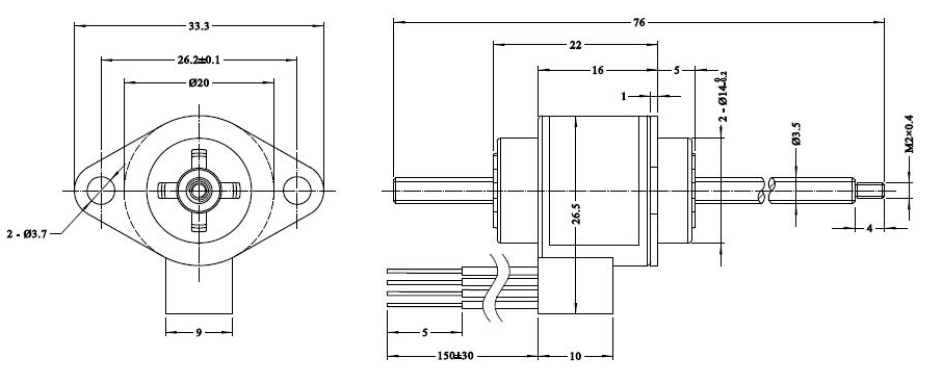

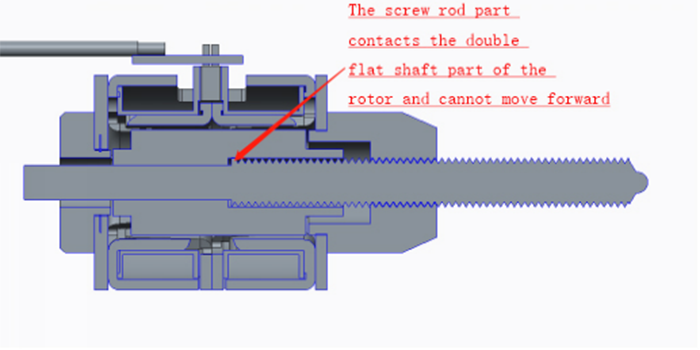

Kutalika kwa screw ndodo ndi 76, kutalika kwa injini ndi 22, ndipo sitiroko ndi pafupifupi kutalika kwa ndodo - kutalika kwa injini:

76-22 = 54mm

Kutalikitsa ndodo yomangira, sitirokoyo imatalika. Chiwombankhangacho chikakhala chachifupi, sitirokoyo imafupikitsa.

Kodi motayi imayenda nthawi yayitali bwanji? Ngati titalikitsa zokopa zowongolera, kodi ulendowo udzakhala wautali?

Kujambula kwa 10mm masitepe mota:

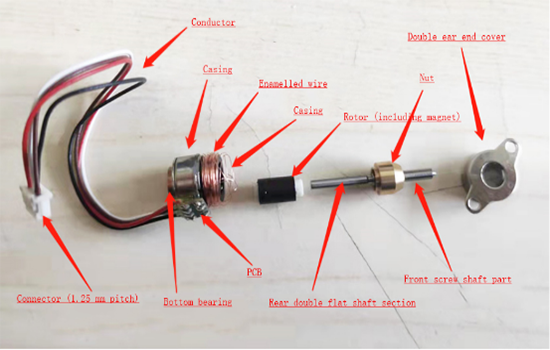

Kutalika kwake ndi 9 mm

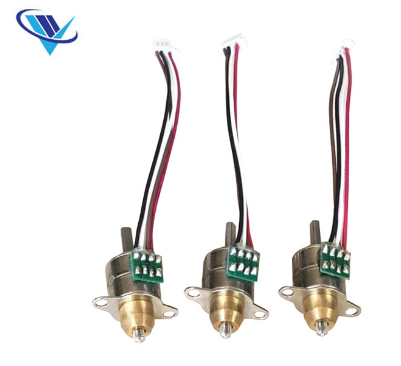

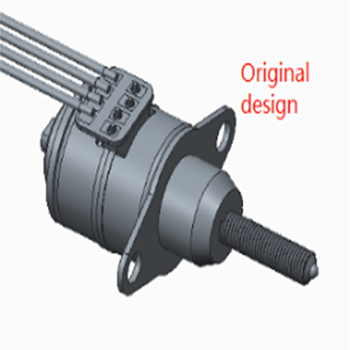

Kapangidwe ndi kapangidwe ka 10mm masitepe mota

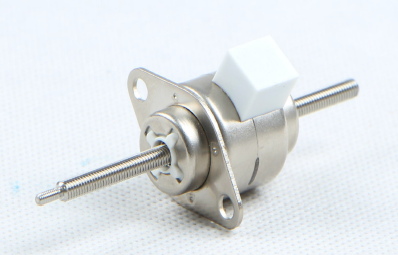

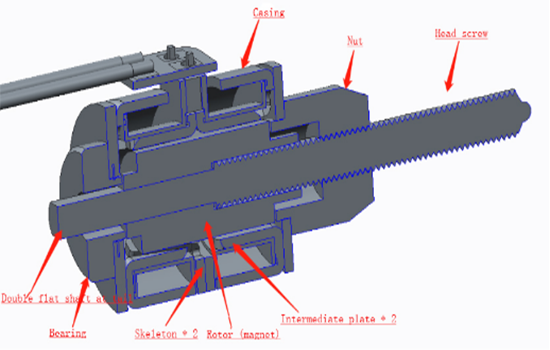

Mapangidwe a 10mm linear stepping motor (3D):

Kapangidwe kamangidwe ka10mm liniya poponda injini(Kuwonongeka kwa 3D):

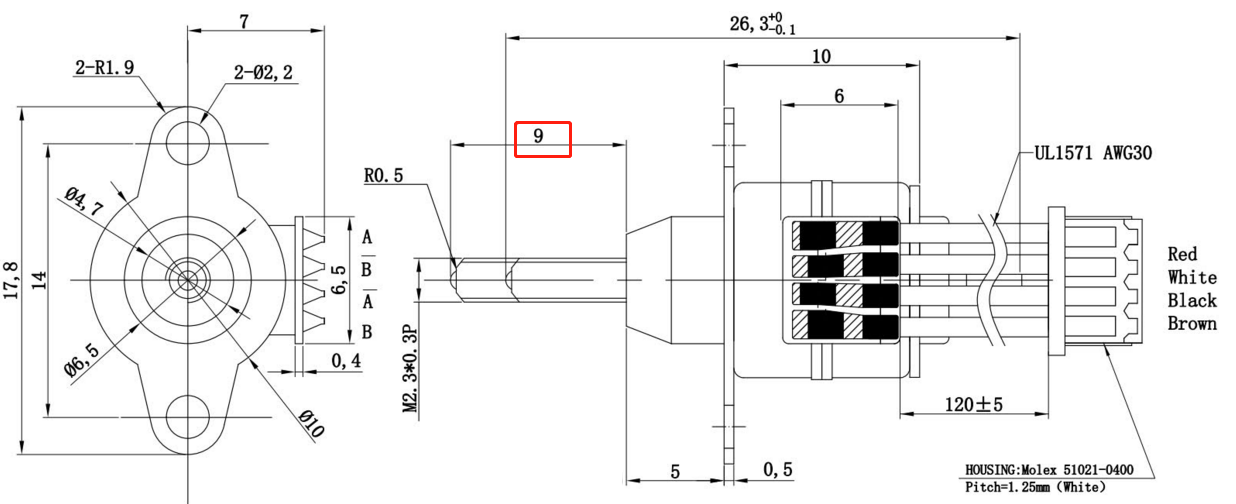

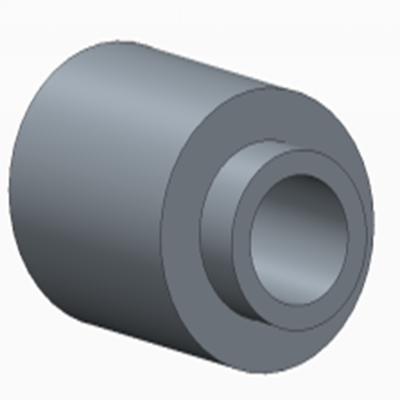

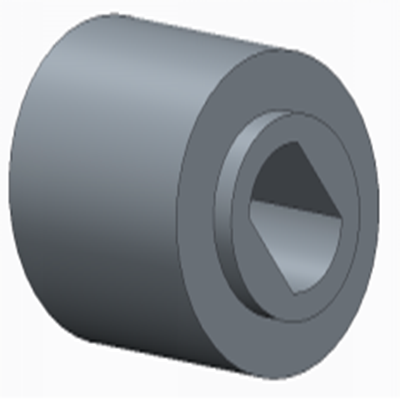

Mapangidwe a rotor:

Mbali imodzi ya rotor ndi yozungulira

Mapeto ena a rotor ndi shaft iwiri

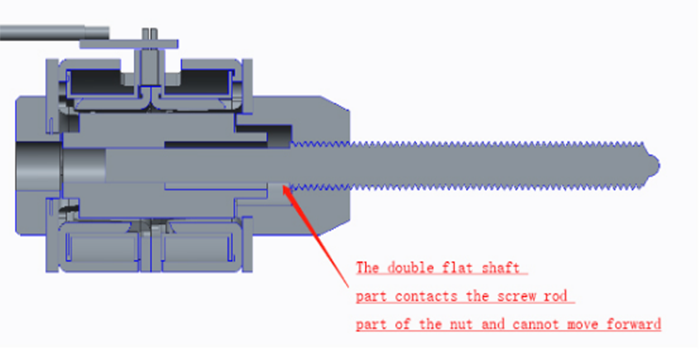

Kugwirizana kwa ma shaft awiri a lathyathyathya a rotor ndi screw rod.

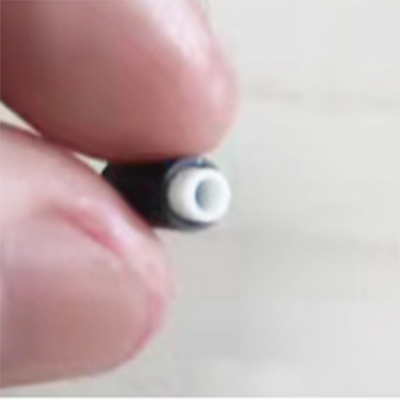

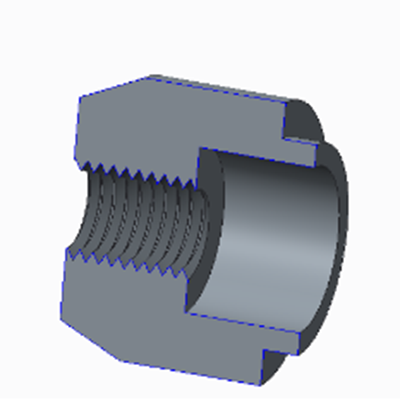

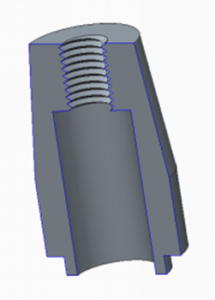

M'kati mwa mtedza:

Mkati mwa nati: M’kati mwa mtedzawo muli ulusi womwe umafanana ndi ulusi wa screw rod.

Mtedza umatembenuza kuzungulira kwa screw rod kupita kutsogolo ndi kumbuyo (kuyenda mozungulira → kuyenda kwa mzere)

Kuwerengera kwa motor stroke: (kuyambira koyambira mpaka kumapeto)

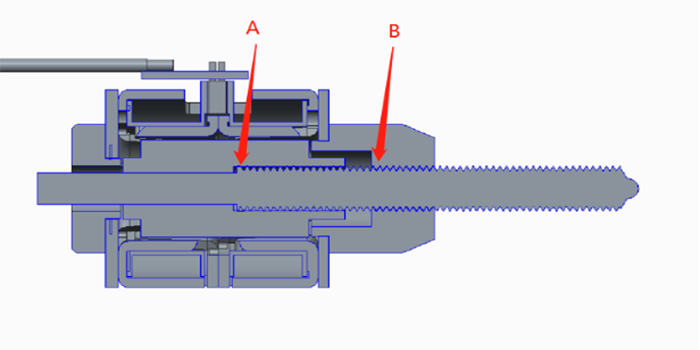

Sitiroko yamoto ndi njira yosuntha screw rod kuchoka ku A kupita ku B (9mm)

Chifukwa chake, kuchuluka kwa shuga m'magazi kumakhala:

Mtunda wa screw ndodo kuchokera ku point A kupita ku point B (yotsimikiziridwa ndi kapangidwe ka mota, osati kutalika kwa screw ndodo)

Popeza ndizopanda phindu kukulitsa ndodo ya screw, momwe mungayendetsere kuyenda kwa mota iyi?

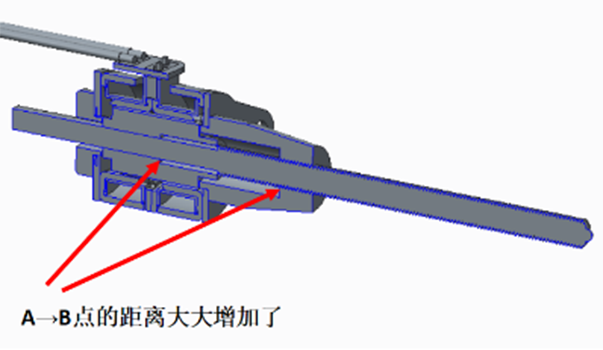

Yankho: Kwezani mtunda pakati pa shaft iwiri yosalala ndi mtedza. Ndiko kuti, mtedza wowonjezera, monga:

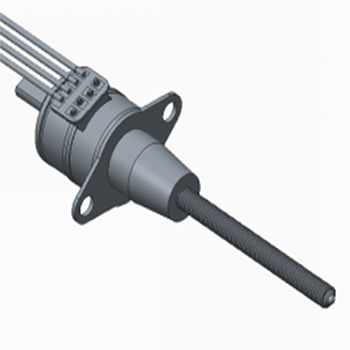

Kenako injiniyo idzakhala motere:

Mwanjira imeneyi, mtedzawo uyenera kukonzedwanso, ndipo chowotcha (chotalikitsa) chiyenera kukonzedwanso kuti chitalikike. Mtengo wake ndi wokwera kwambiri, choncho nthawi zambiri sizili choncho.

Njira ina yoganizira:

Pangani motalika.

Pakali pano, kutalika kwa injini ya 10mm ndi 10mm.

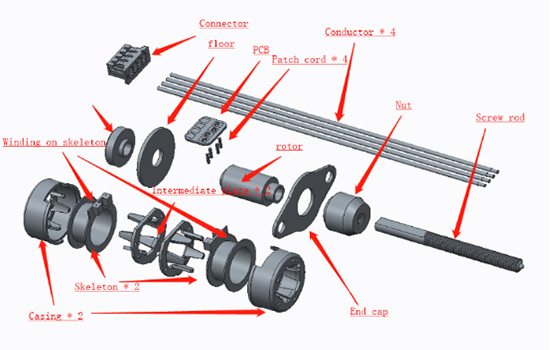

Choyikapo, kalasi yapakati ndi mafupa onse amalizidwa.

injini ikatalikitsidwa, zikutanthauza kuti casing+intermediate class+skeleton+rotor italikitsidwa palimodzi.

Mtengo wake ndiwokwera kwambiri !!!

Nthawi yotumiza: Nov-25-2022